SAT Plating Resources

- View All

- Case Studies

- Education

- News

Dear friends and colleagues, I am fortunate to have one of the industry’s most important events–the Reindustrialize Event–held in my backyard. From June 24th – 25th, I will be attending this event being held at Newlab in Detroit, Michigan to discuss the reindustrialization of American manufacturing and to see how SAT plating can play a […]

Supply chains are one of the great modern marvels that excel at producing products at a reduced cost and with a high degree of efficiency. However, what these supply chains have produced in terms of efficiency has come at the cost of increased fragility. When something goes awry–a shipment arrives late, a part was produced […]

The aerospace and defense (A&D) sector is the backbone of national security, providing the advanced technologies, systems, and capabilities that protect our nation and project American power around the world. In an era of heightened geopolitical tensions, supply chain disruptions, and the need for greater self-reliance, the importance of a robust and resilient domestic manufacturing […]

As the world is still reeling from the aftershocks of the response to COVID-19, A&D supliers are becoming increasingly gun-shy with fixed-price contracts from the DoD. While the Pentagon is trying to stretch each dollar and ostensibly watch out for the taxpayer, the bulk of the risk is ultimately transferring to A&D OEMs and even […]

The COVID-19 pandemic response saw borders shut, businesses closed, and aerospace and defense (A&D) supply chains from tier X suppliers on down to OEM halted in their tracks. The crisis spotlighted the critical need for a resilient supply chain that can withstand not only the current challenges but also future unforeseen global disruptions. Through the […]

Once considered secondary players, the high-value-added niche suppliers have now cemented their role as indispensable players in the complex world of defense production. The transformation of these specialized manufacturers from peripheral participants to central contributors is not just a story of innovation and adaptation, it is a testament to the shifting needs of a sector […]

Small suppliers play a pivotal and often undervalued role in aerospace and defense manufacturing. Their agility and specialized expertise, particularly in the area of performance plastics and plating, make them indispensable and valuable assets in the broader supply chain. In an industry where precision and reliability are paramount, companies like SAT Plating offer bespoke solutions […]

As industries across the globe strive for innovation and improvement, the question often arises: “Is it time for a redesign?” However, acknowledging that it’s time to redesign a product and actually taking the first steps are two different beasts, which is where injection molding comes in. Injection molding combined with plating is a marriage of […]

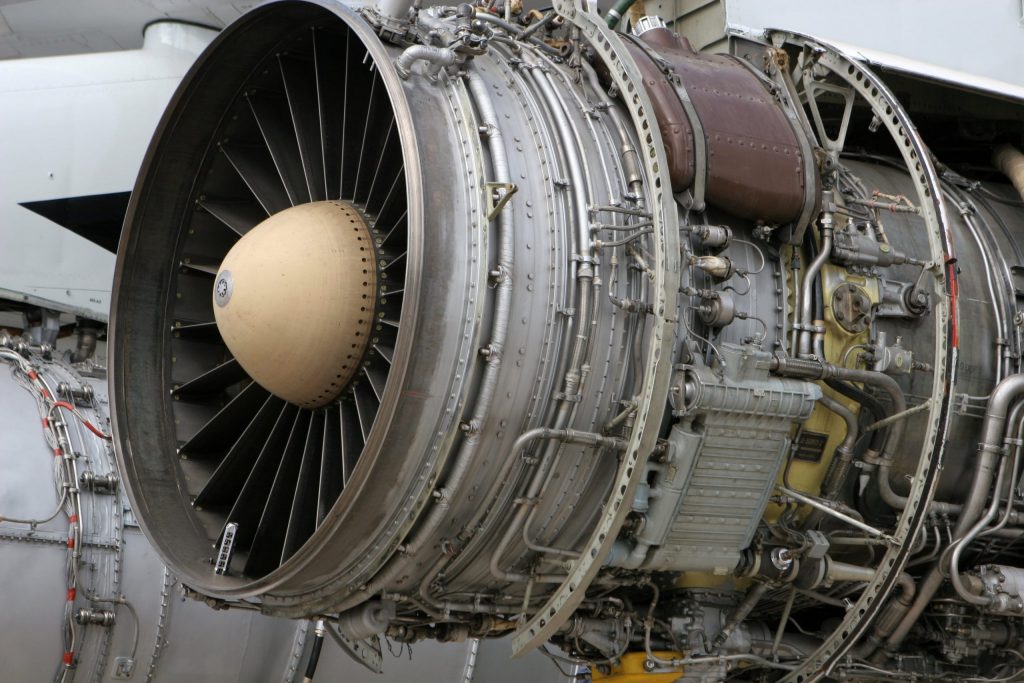

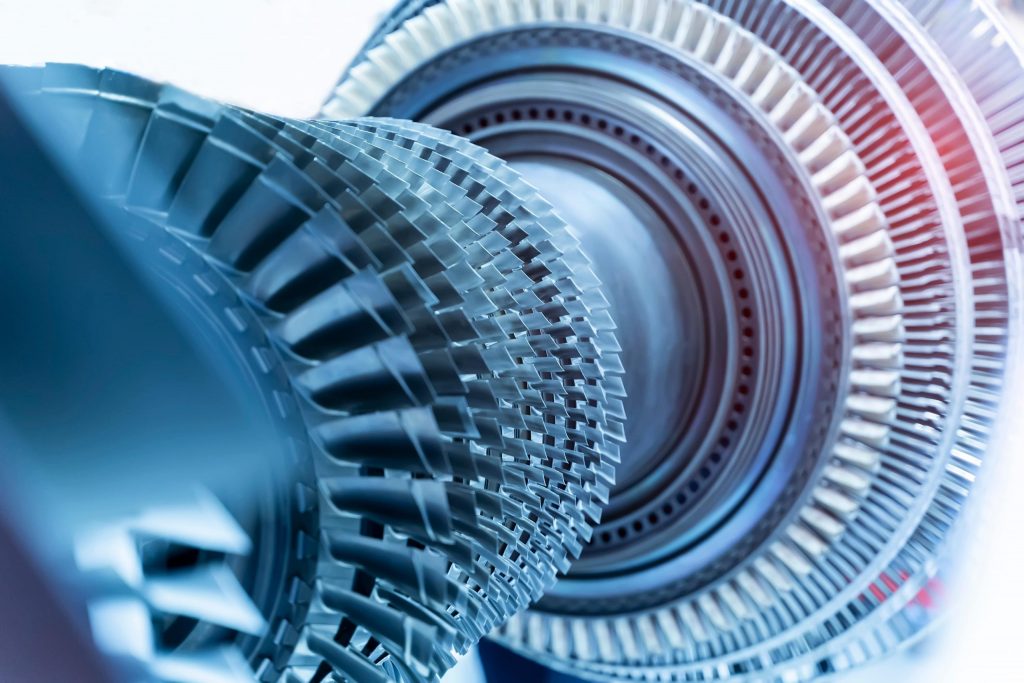

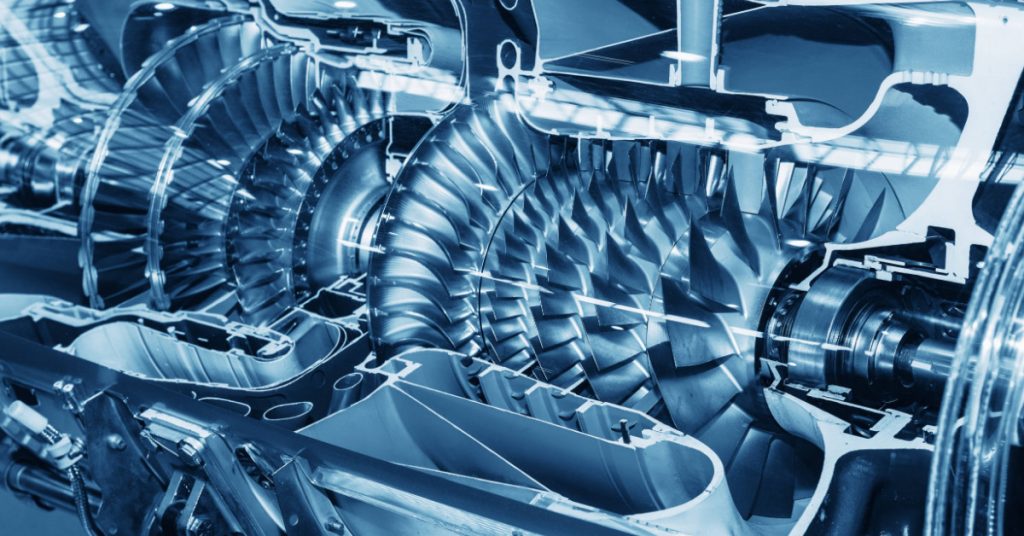

Making aircraft parts lighter is one of the easiest ways to improve the effective range of the aircraft; the less weight a turbine must move, the farther it can go. At the forefront of this race for lightweighting lies the integration of plated plastics and composite materials into aircraft components. This transformative advancement of aviation […]

Corrosion resistance has always been a crucial part of Aerospace & Defense (A&D) development because of the extreme conditions that aircraft and military products are subject to. This property is essential as corrosion, a naturally occurring process, can lead to the degradation of critical materials over time, compromising their structural integrity and function. Especially aboard […]

Thermal conductivity is a critical factor in selecting metals for electroplating applications, as it determines their ability to efficiently dissipate heat and transfer electricity. Metals like silver, copper, gold, are excellent for high thermal conductivity and enable effective heat dissipation, while nickel offers transfer capabilities, conductivity, and EMI Shielding properties. Silver and copper are extremely […]

In the ever-evolving landscape of defense technology, the integration of advanced materials is crucial to enhance efficiency and effectiveness. One such material that holds great promise is electroplated carbon fiber. By harnessing the lightweight yet robust characteristics of carbon fiber, aerospace and defense companies can benefit from improved fuel efficiency, increased payload capacity, and even […]

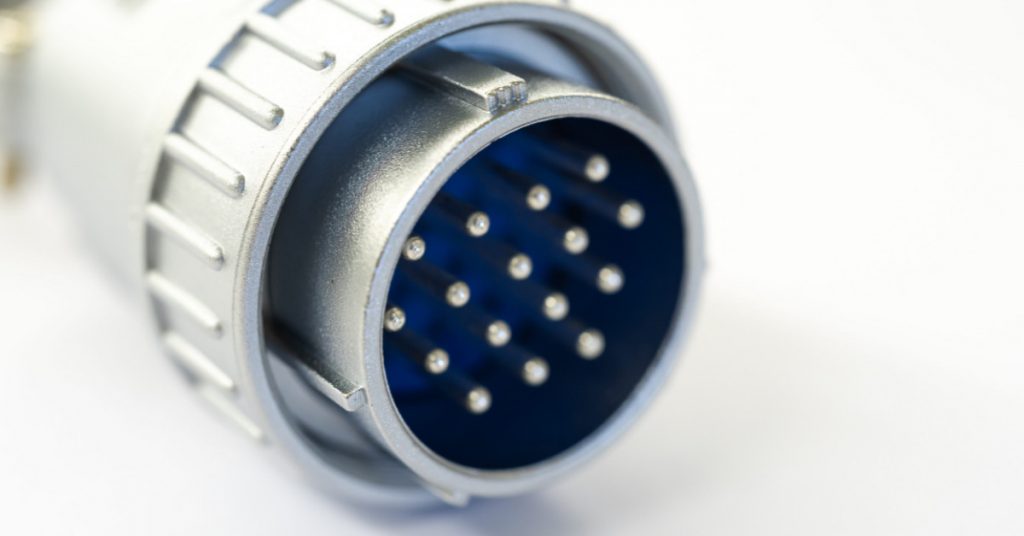

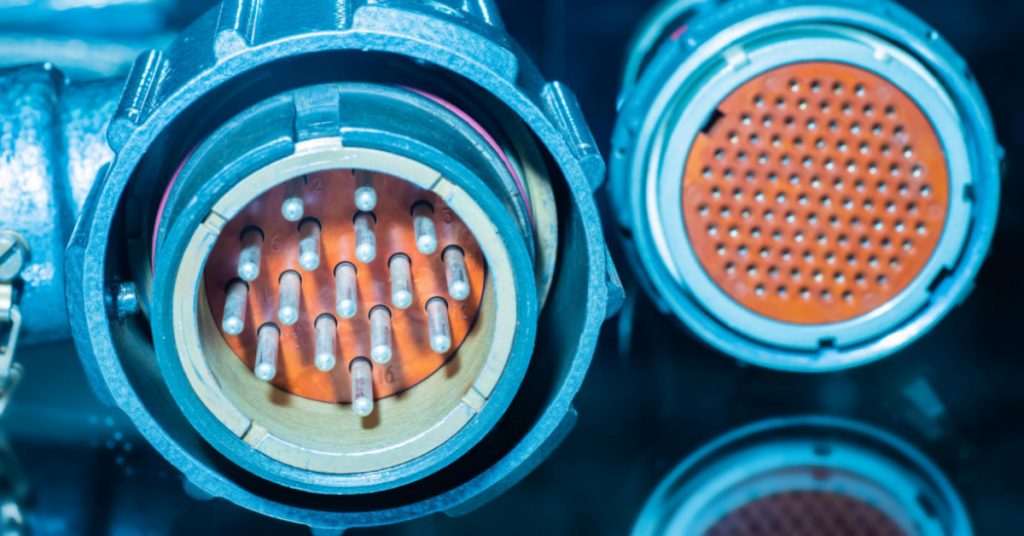

Connector specifications are becoming more stringent in aerospace and military applications and rightfully so. Operating aircraft at hundreds of knots per hour at tens of thousands of feet above the earth requires strict standards that virtually eliminate the possibility of failures. Issues like electromagnetic interference, heat, and vibration must be mitigated all while using lightweight […]

Aircraft are flying systems of complex interconnected computers that are constantly communicating with each other. These onboard electrical systems are arranged in hierarchical interconnected networks that enable communication among different devices. Several interconnections are required for signal transmissions, power distribution, and proper functioning of all components. All of these relays need connectors, which are the […]

Recently, SAT Plating was honored to appear in an Omnetics white paper discussing reliable connectors on LEO satellites. The white paper discussed the necessity of greater resilience for materials used in the manufacturing of LEO satellites. Connectors are a key part of LEOS to aid in radiation protection, EMI shielding, and temperature resistance and must […]

Different connectors have different uses based on the substrate and plating material. Substrate selection for the base material of a composite connector is crucial in aerospace and defense, and other uses because of its role in determining the connector’s performance and reliability. The substrate material must be able to withstand the harsh conditions, including high […]

The U.S. defense industrial base is the network of companies, research institutions, and other organizations that produce goods and services for the U.S. military. It is a critical component of the U.S. national security apparatus, providing the military with the equipment, technology, and other resources it needs to defend the country. Surface finishing is a […]

The F-35 is currently the most advanced fighter jet in the world. Its performance, advanced avionics, speed, and flight ceiling are peerless and give the US military and coalition forces an asymmetrical advantage. While the F-35 is currently king of the skies, continued advancement across all domains of technology is needed to ensure airspace superiority. […]

As more and more US defense companies are on-shoring their manufacturing operations, it’s imperative that they comply with ITAR standards. We break down what ITAR is, how United States Defense manufacturers can ensure they are compliant, and why ITAR compliance is a driving factor in on-shoring efforts. What is ITAR? The International Traffic in Arms […]

Composite manufacturing has revolutionized how waveguide and satellite antenna components are made in multiple industries. From spacecraft technology and satellite communications to aerospace and helicopters, composite materials have been utilized to reduce weight, increase efficiencies, and enhance the durability of waveguides and antennas. Spacecraft technology Composite materials are widely implemented in spacecraft structures, allowing engineers […]

What is ITAR? The International Traffic in Arms Regulation (ITAR), a set of US regulations, affects the manufacture, sale, and distribution of defense and military-related technologies on the United States Munitions List (USML). The restricted defense and military technology and data include: Launch vehicles Aircraft Military electronics Spacecraft Guns and armament The US Munitions List […]

From Hexcel to Collins Aersopace, more and more aerospace leaders are embracing the use of innovative composites in both aircraft and related parts. Keep reading to find out which companies are innovating in the use of composites and learn about the extensive benefits of converting to these high-tech materials. Hexcel Hexcel is a major supplier […]

From General Electric to Raytheon, more and more aerospace and defense companies are turning to composites to cut weight. Keep reading to learn which companies are expanding their use of composites and all the benefits they’ve discovered as they’ve converted to these high-tech materials. General Electric General Electric has started building its commercial aircraft engines […]

Aerospace and defense engineers are paying increasing attention to thermoplastic composites as a cost-efficient option to replace metallic and thermoset composite parts. What are thermoplastic composites? According to Science Direct, “thermoplastics are a class of polymers that can be softened and melted by the application of heat, and can be processed either in the heat-softened […]

Aerospace design engineers looking for a cost-effective, durable, and reliable option for lightweighting connectors and connector housings should consider transitioning from aluminum and steel alloys to plated polymer connectors. Why Plated Polymers for Aerospace Connectors? The aerospace connector industry has been through many transformations throughout history. From the early days of flight to today, there […]

Lightweighting is critical in today’s aerospace design engineering. Since connectors and connector shells are integral to any aircraft, it’s worth looking at plated composite and polymer connectors for reducing overall weight. Lightweighting with Innovative Plastics Reducing the overall weight of an aircraft or any airborne product will increase energy efficiency and decrease fuel consumption. In […]

There are thousands of connectors on airplanes, defense systems, and vehicles. The high performance and highly technical interfaces utilized in these electronic systems require durability, corrosion resistance, and production consistency. These specifications make the concept of using injection molded and plated connectors a smart choice for any advanced wiring system. More specifically, injection molding with […]

From electric vehicles and consumer electronics to medical devices and airplanes, EMI shielding plays a vital role in preventing disruptions in essential areas of our everyday lives. What is EMI Shielding? According to ScienceDirect, electromagnetic (EM) shielding is an “electromagnetic shell (entity or nonentity) made of the shielding materials (conductive or magnetic material), which forms a […]

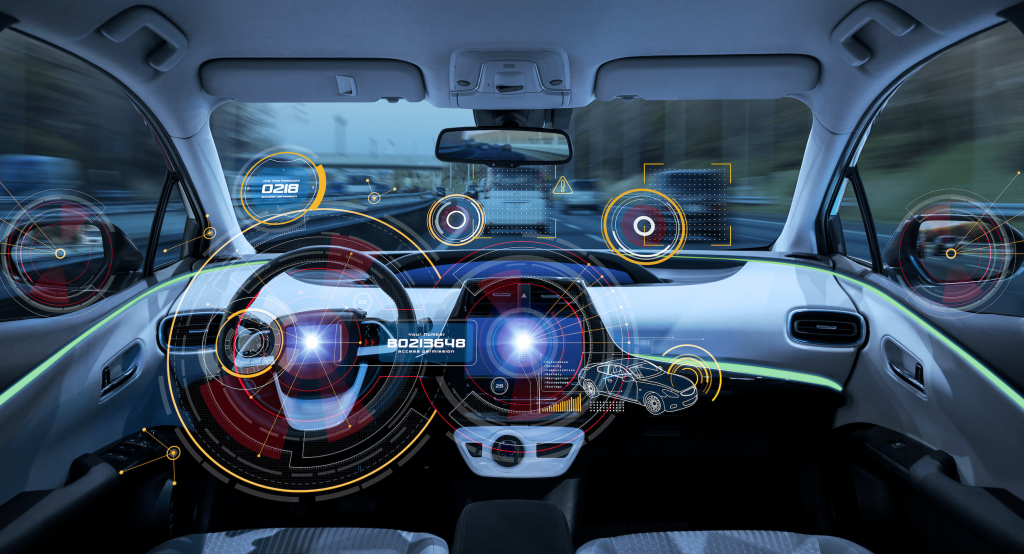

Electromagnetic Interference (EMI) shielding is a common concern in many vehicles, particularly today’s new cars, which feature significant electronic functions like GPS and self-driving functionality, coupled with Electric Vehicle (EV) technology and the accompanying power and battery requirements. EMI shielding aims to create electromagnetic immunity, protecting electronic equipment in the car from the challenges of […]

EMI shielding is used in many types of medical devices to prevent equipment malfunction or anomaly from electrical, magnetic, or radiofrequency signal interference, and thereby, promote patient safety and reduced healthcare costs. What is EMI? EMI stands for electromagnetic interference, which can cause unwanted signal disruption in medical equipment. It can occur when three […]

In an automotive industry that’s bullish on electric vehicles, electromagnetic interference (EMI) shielding is becoming even more critical to manufacturers and their tier one and tier two suppliers. Electric Vehicle (EV) manufacturing inevitably requires installing electronic systems into a confined spaces and somehow keeping the electromagnetic energy generated from these systems from “crosstalking” and causing […]

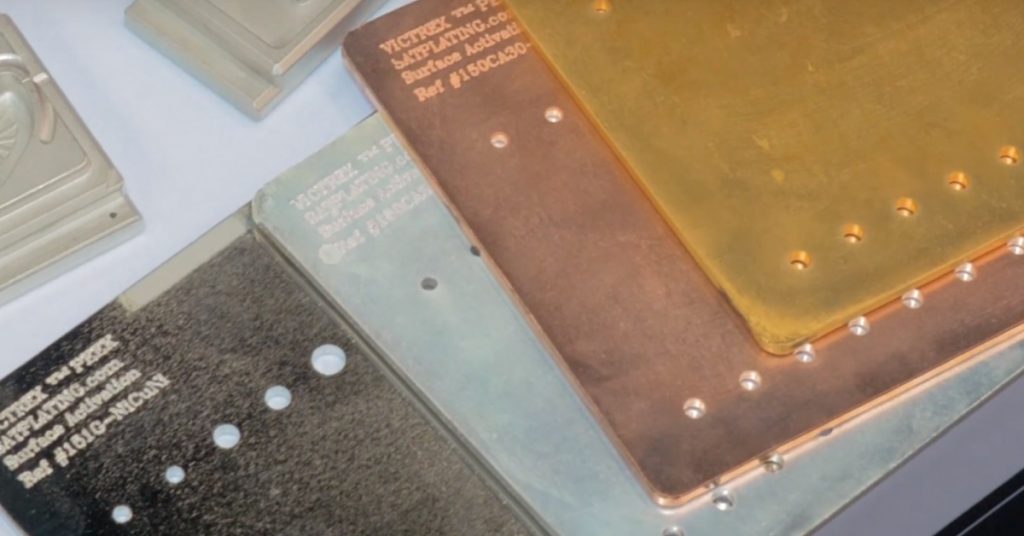

High-performance plastics can present professional plating challenges, though the properties that plating brings make it worth the effort it takes to meet those challenges. Why Plate on Plastics? Polymers like PEEK, Ultem, and Carbon Fiber can be incredibly efficient for aerospace, defense, medical, and other industries. Engineers choose plating to add structural integrity, EMI shielding, […]

Nickel plating application is a metal coating process that involves electroplating nickel onto the surface of another object to either shield it (from corrosion or EMI), resurface it after wear, or to add new qualities like a decorative finish or electrical conductivity. This article will explore how and why this process works. Nickel can be […]

Technology advancements in industrial electroplating have been a direct result of developing and increasing use of PEEK, Ultem, and other high-performance polymers in manufacturing. Tech Advancements Lead Industrial Electroplating Innovation As technology races forward, industrial designers and engineers are constantly looking for polymer materials with greater thermal stability and higher strength-to-weight ratios that can operate […]

For those looking for a technologically-advanced, yet long-tested surface protection process at an affordable price, electroless nickel plating services may be the perfect solution. Reasons to Consider Electroless Nickel Plating Services Nickel plating is vital for many commercial applications and industries, particularly aerospace and automotive. It will protect metal parts from corrosion and increase their […]

PEEK, Ultem, and other high-performance polymers, coupled with electroplated metals, have helped bring about significant technology advances in commercial plating and, more specifically, EMI shielding. Here, we will cover why EMI shielding is essential and the options available for today’s engineers. What is EMI Shielding? Electromagnetic interference (EMI) shielding helps protect against signal disruption, preventing […]

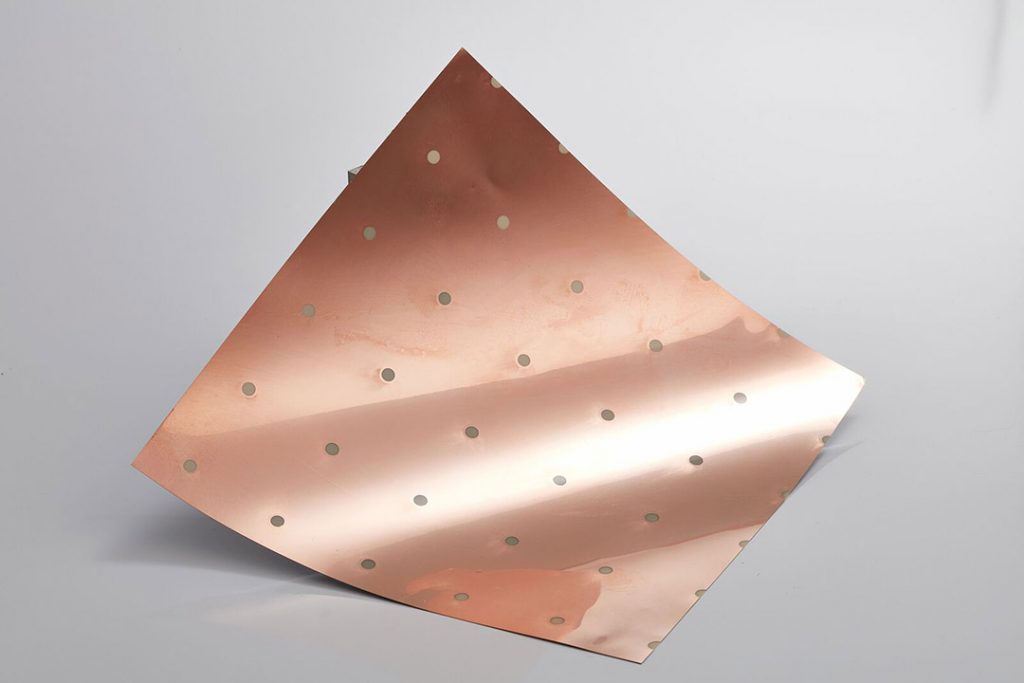

When plating engineered polymers and resins like PEEK and Ultem, the benefits of copper include excellent electrical and thermal conductivity. What are the pros and cons of copper plating engineered plastics like the innovative polymers PEEK and Ultem? In aerospace, medical, and industrial applications, copper can be used to add beneficial qualities like electrical conductivity, […]

Nickel plating is one of the most versatile plating options available and its popularity is likely to continue to grow in the aerospace and defense industries. The evolving needs of engineering teams in the fields will likely continue to drive ongoing advancements in the nickel plating industry. What is Nickel Plating? A coating of nickel […]

What Is Electroplating? A popular metal finishing process, electroplating is used in a variety of industries for a wide range of applications. The electroplating process uses an electric current to deposit a thin layer of material on top of an object. It’s primarily used to increase wear resistance, protect against corrosion, provide conductivity , or […]

Hello, I’m Richard Hooper and this is SatTV week. Now, I’m pleased to be joined by Will Wallace of SAT plating. Q: Will, thank you very much for joining me today. Tell me a little bit more about the company because it’s quite specialized. A: “At SAT Plating we specialize in plating high-performance plastics on […]

The Cutting Edge of Metallizing High-Performance & Composite Plastics SAT Plating LLC, a leading plastics plating company, is pleased to announce they will be exhibiting at the upcoming Satellite 2020 Conference and Exhibition: March 9-12, 2020 at the Walter E. Washington Convention Center in Washington, DC. SAT Plating will be exhibiting in booth #2324. SAT […]

The Cutting Edge of Metallizing 3D & High-Performance Plastics SAT Plating LLC, a leading plastics plating company, is pleased to announce they will be exhibiting at the upcoming MD&M West Show in Anaheim, CA from February 11-13, 2020 at the Anaheim Convention Center. SAT Plating will be exhibiting in booth #1292. SAT Plating has technology-enabling […]

Satellite Aerospace and Defense Industries The competitive nature of technology companies – in particular, Satellite, Aerospace and Defense Industries – demand components be smaller, smarter, lighter and more cost-effective. That’s a tall order made achievable with SAT Plating’s Surface Activation® and SelectPlate™ technology. It wasn’t that many decades ago that the only engineers obsessed with […]

July 17, 2019 | Troy, MI SAT Plating LLC, a leading plastics plating company, is pleased to announce they will be exhibiting at the upcoming 2019 IEEE International Symposium on EMC + Signal and Power Integrity in New Orleans, LA from July 22-26, 2019 at the Ernest N. Morial Convention Center. SAT Plating is in booth […]

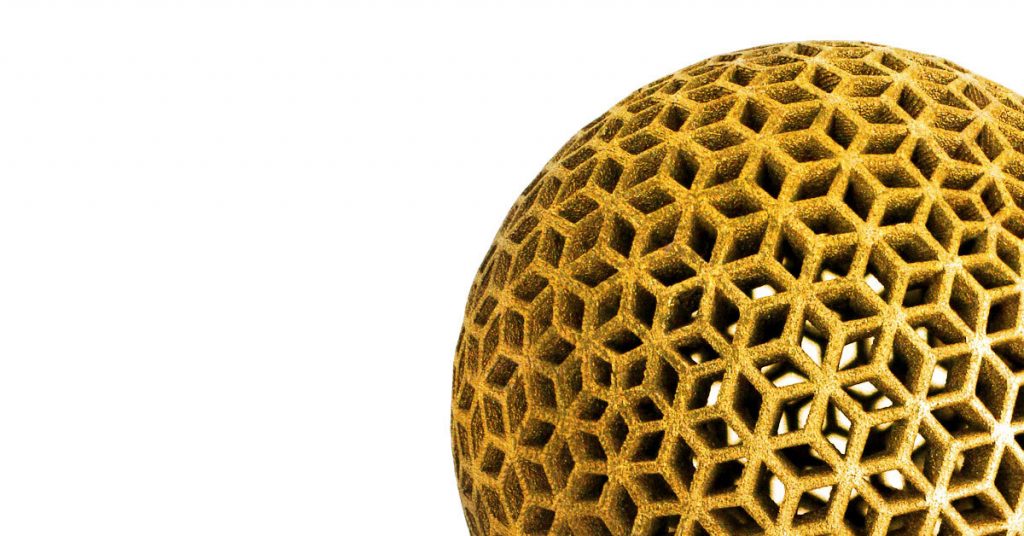

May 6, 2019 | Troy, MI SAT Plating LLC, a leading plastics plating company, is pleased to announce they will be exhibiting at the upcoming Rapid + TCT 2019 Show in Detroit, MI from May 21-23, 2019 at the Cobo Center. SAT Plating will be exhibiting in booth #449. SAT Plating has technology-enabling plating capabilities […]

In Part One, we discussed product development considerations with polymer selection, part geometry, and molding conditions. In today’s article our focus is on adding functionality to your product, part processing and finishing considerations: Functional – Structural – Performance Platings The most common functional metal platings are Copper and Nickel due to their relatively low cost […]

In today’s economy, excellence is the price of entry and cost containment is sometimes the difference between product success or failure. All too often, it’s common for a plastic part to be fully designed before the plater is consulted… only to find the going-in assumptions need revisiting. Likewise, many good ideas get discarded based on […]

Selective metal plating only where you need it with strong adhesion on medical-grade polymers… visit us in Anaheim. January 18, 2019 | Troy, MI SAT Plating LLC, a leading plastics plating company, is pleased to announce they will be exhibiting at the upcoming MD&M West Show in Anaheim, CA from February 5-7, 2019 at the […]

High adhesion + superior finish on PVC/CPVC SAT Plating is pleased to announce that it can now electroplate parts and products made with PVC and CPVC resins, including films | fibers | injection-molded | 3D printed parts. SAT has robust processes for obtaining great plating adhesion to PVC CPVC, without the need to media blast […]

Improve designs, reduce costs, & know before you go One of the most valuable services we offer to customers is the metal plating of prototype, R&D, and pre-production polymer samples. These samples are invaluable to product development because they confirm design strengths and expose needed improvements – permitting relatively inexpensive changes or modifications before requirements […]

Whether called 3D printing, rapid manufacturing, or additive manufacturing, this industry is experiencing explosive technical growth. With each passing year customers have an ever-increasing choice of manufacturing techniques and machinery, but also an equally expanding selection of polymer choices with improved performance characteristics. SAT Plating is keeping abreast with this changing landscape by participating and […]

Plating high-performance plastics presents challenges for which many engineers and product development teams are not prepared. High scrap rates and costly reworking of parts is a common story from those who have ventured down the plating path. Let’s explain the basics and keep your next project on track from day one. Metals are better conductors [...]

The Tier 1 supplier of the Ford Motor Company was in search of a company to create and supply chrome plating for the key fobs of their Lincoln vehicles. They needed a company that had the ability to plate only selected areas on the part while not compromising the fob’s functionality and sleek design. SAT created the process to chrome plate the fobs and meet high-volume automotive quality standards.

Welch Allyn was looking for a company capable of creating a long-lasting probe tip for their Pro 6000 Ear Speculum. They needed a company capable of plating the probe tip without compromising its already tight and sleek design, while also ensuring that the tip was durable. They needed a company that could plate the PC/ABS portion of the tip with a reliable and resilient adhesive. That’s where we stepped in to help.