Plating Kapton® (PI)

Using our highly controlled Surface Activation® technology, we can plate Kapton® (PI) for both functional and decorative purposes. When preparing the plastics to be plated, no abrasive blasting or chemical erosion is needed, ensuring that there is no dimensional change to your part.

Why Use Kapton® (PI)?

Kapton® (PI) can withstand various forms of extreme temperature while never compromising its mechanical properties and its structural stability. This temperature tolerance affords it the ability to be applied to various extreme environments that range from space travel to vascular catheters.

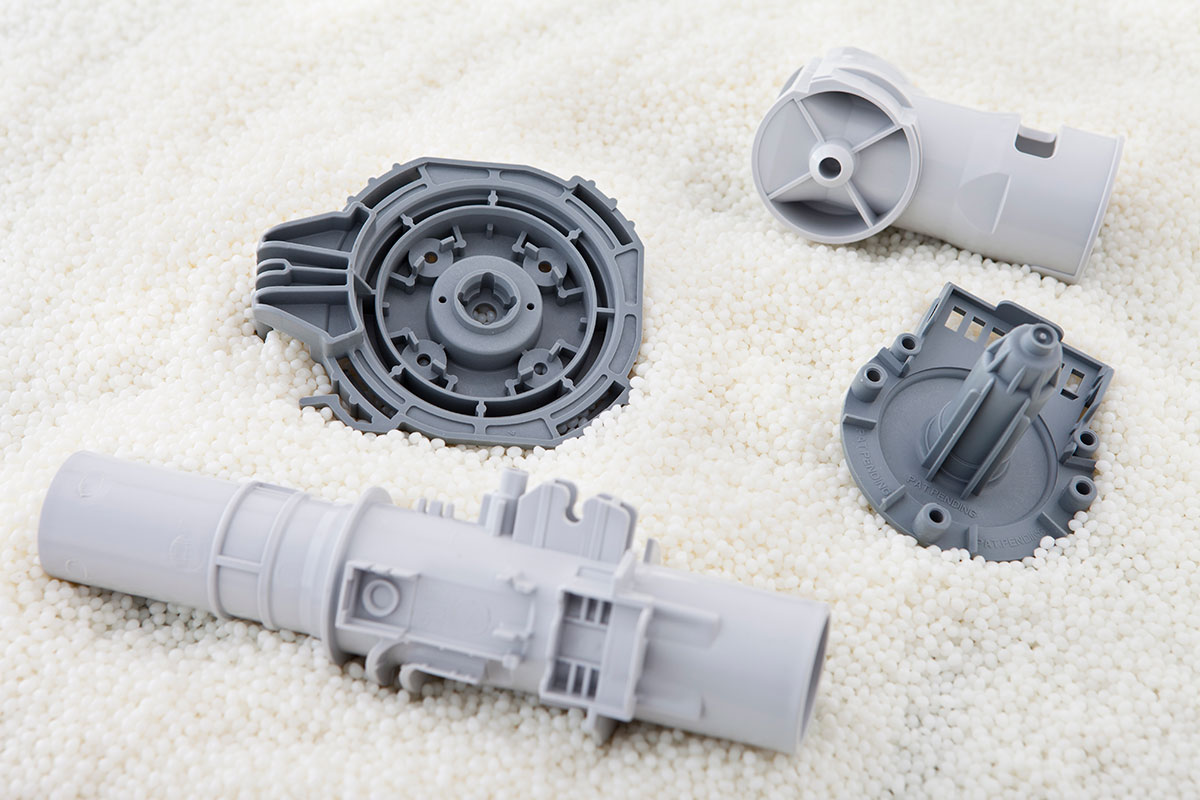

Kapton® (PI) also offers great flexibility due to the malleability of the material. It can be 3D printed, injection molded, or even thermoformed, allowing the material to fulfill various roles that traditional metal cannot.

Kapton® (PI) offers a high-resistance to various chemicals such as acid, alcohol, and halogenated solvents. Its high resistances afford it a great degree of longevity since it deters corrosion, as well as being resistant to stress cracking and being flame retardant.

It should be noted that Kapton® (PI) is fairly expensive when compared to other thermoplastics and it cannot be used above its glass transition temperature unless specific steps have been taken.

A Closer Look at Kapton® (PI)

PI—also known as Polyimide—is a heat resistant polymer consisting of reoccurring amide groups as a major part of the main polymer chain. PI boasts a high heat-resistance that affords it a plethora of applications ranging from fuel filters, to insulating film on magnetic wires, to optical fibers used in the medical field.

Kapton® (PI) is known for its thermal stability, which offers it great chemical resistance as well as dynamic mechanical properties. With a melting point of 752 °F (400 °C), Kapton® (PI) offers the ability to maintain its structural properties of low creep and high tensile strength during continuous exposure to temperatures up to 450 °F (232 °C) and short exposure to temperatures up to 752 °F (400 °C). In addition to its thermal stability, Kapton® (PI) also offers a natural resistance to combustion and does not need to be mixed with a flame retardant.

Kapton® (PI) is also a material that offers great structural flexibility. This allows dynamic application in regard to how the material can be employed from situation to situation. Along with being flexible, Kapton® (PI) is also incredibly lightweight, which is utilized in the electronics industry where it is especially useful for cables and wires.

Kapton® (PI) also functions greatly when exposed to cold temperatures. The material can still maintain its structural properties when subjected to temperatures around -518 °F (-270 °C). This property has led to Kapton® (PI) being used in aerospace transportation since it thrives in both extreme hot and cold environments. It is especially common in aerospace insulation (as well as other forms of insulation).