Plating Carbon Fiber

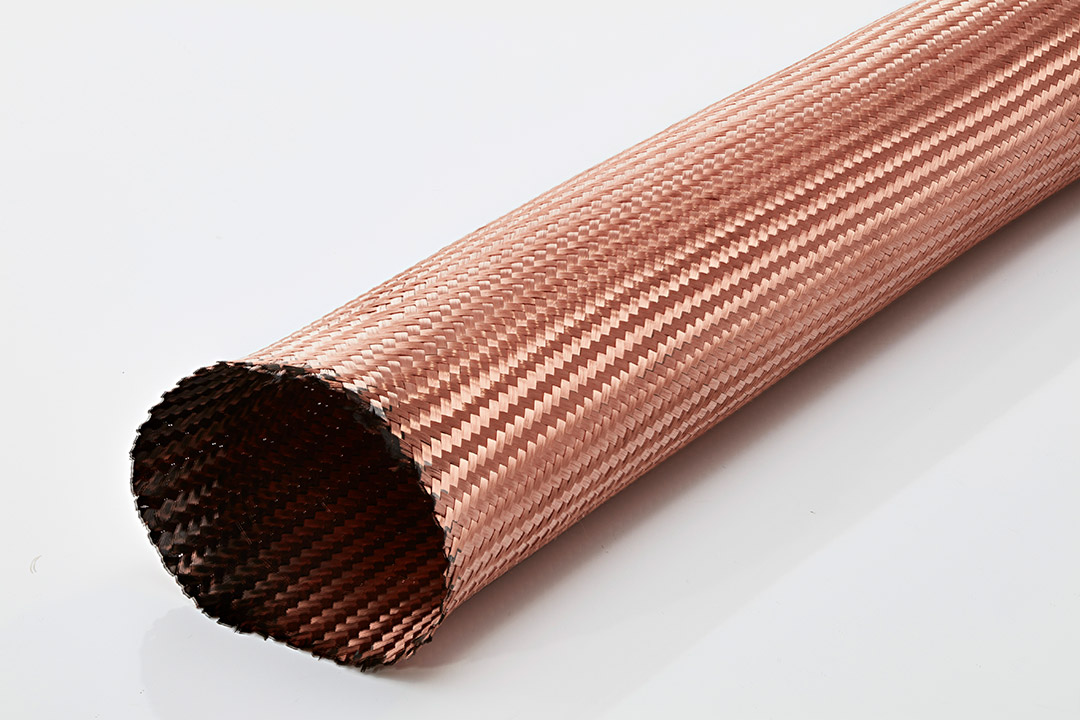

Our proprietary plating methods allow us to metalize carbon fiber.

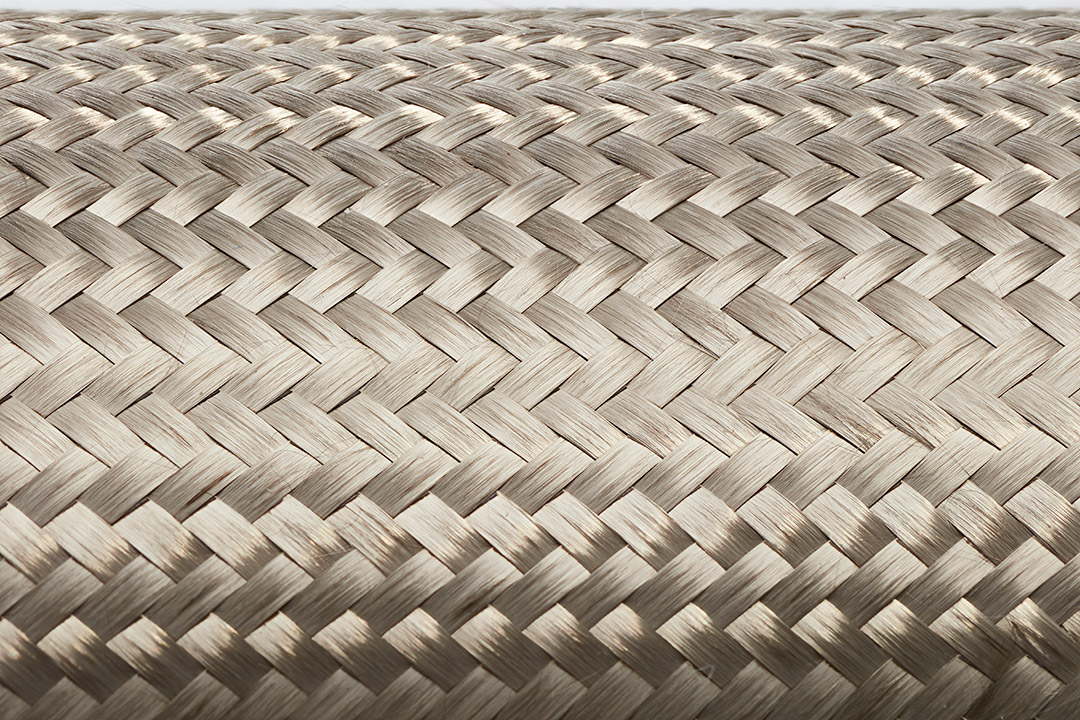

Whether its natural carbon fiber weave or epoxy impregnated carbon fiber, we can achieve strong adhesion on the surface. As you can see, plated carbon fiber can be used for EMI shielding, adding conductivity, or even appearance finishing.

Why Use Carbon Fiber?

Metal replacement: the strength-to-weight ratio of carbon fiber is outstanding and can further maximized when plated with a metal.

Carbon fiber is also a great material for high-heat applications.

Its ability to be used as a composite material also gives Carbon Fiber great flexibility in regard to the properties it can take on. The material can be reinforced to increase or decrease its rigidity, increase its heat resistance, or even increase its tensile strength.

A Closer Look At Carbon Fiber

Carbon fiber is an incredibly strong and lightweight material that can rival steel in its properties, boasting five times the strength of steel and double the stiffness. The material’s strength vs weight makes it ideal for implementations in extreme environments, such as aerospace military applications.

Carbon fiber can be combined with other materials to increase its resistance in certain environments and adding to its already high tensile strength. This affords the material the ability to have dynamic application in regard to its specialization for specific environments. For example, if Carbon Fiber is composited with Graphite, it can increase the materials heat resistance

Carbon fiber is also known for its conductive properties. The material offers the ability to conduct low currents in its raw form. When interwoven between threads of fabric, the material can conduct and sustain temperatures upwards of 212 °F (100 °C).

The lightweight of carbon fiber can be attributed to the material’s composition. Carbon fiber is generally between five to ten micrometers in diameter and is composed of carbon atoms. Its composition gives the material a high strength-to-volume ratio since several thousand carbon fibers are grouped together into strands, where they are then interwoven with other strands to create the material.