Plating FDM Materials

The FDM printing process is the most commonly used rapid prototype method.

Some common materials used with FDM include Ultem, Nylon, ABS and other readily available materials. This wide scope of materials selection allows FDM prototypes to be used for many aerospace, medical, industrial, and consumer applications.

Plating SLS Materials

The SLS process creates parts at a higher speed, but with good resolution. Plastic particles are fused together via a laser beam, allowing the use of higher meltpoint polymers, giving SLS fabricated parts very high structural strength. SAT can plate the materials with a variety of surface treatments.

Plating SLA Materials

SLA parts can be made very quickly, and with fine detail, however the UV curable acrylic polymers used in the process yield parts with low structural strength. SAT can add metal platings to such parts, which increases their tensile and flexural strength, making them more functional.

A Closer Look at 3D Printing

3D printing is a process in which a three dimensional object is created—or printed—through the use of computer control. 3D printing uses computer aided design (CAD) to quickly and accurately fabricate a 3D model through the uses of additive manufacturing. Additive manufacturing is a process in which material is stacked layer upon layer to create a 3 Dimensional model. Many different types of materials can be used for 3D modeling, as well as plenty of different processes in which 3D modeling can be utilized.

SLA 3D Printing

SLA—also known as Stereolithography—is a type of 3D printing in which photopolymerization is used to stack layers of material to create a 3D product (additive manufacturing). Light is used in this process to link polymers together, which is how the layers of plastic adhere to one another to form the product. SLA is primarily used for prototyping and 3D modeling in the medical field due to its quick turnaround time.

SLA is commonly used for medical modeling. Accurate 3D models of body parts are recreated through computer scans and then fabricated through the use of SLA printing, where they are then examined and studied. SLA is also commonly used for prototyping since 3D models can quickly and cheaply be produced for tests and mock-ups.

FDM 3D Printing

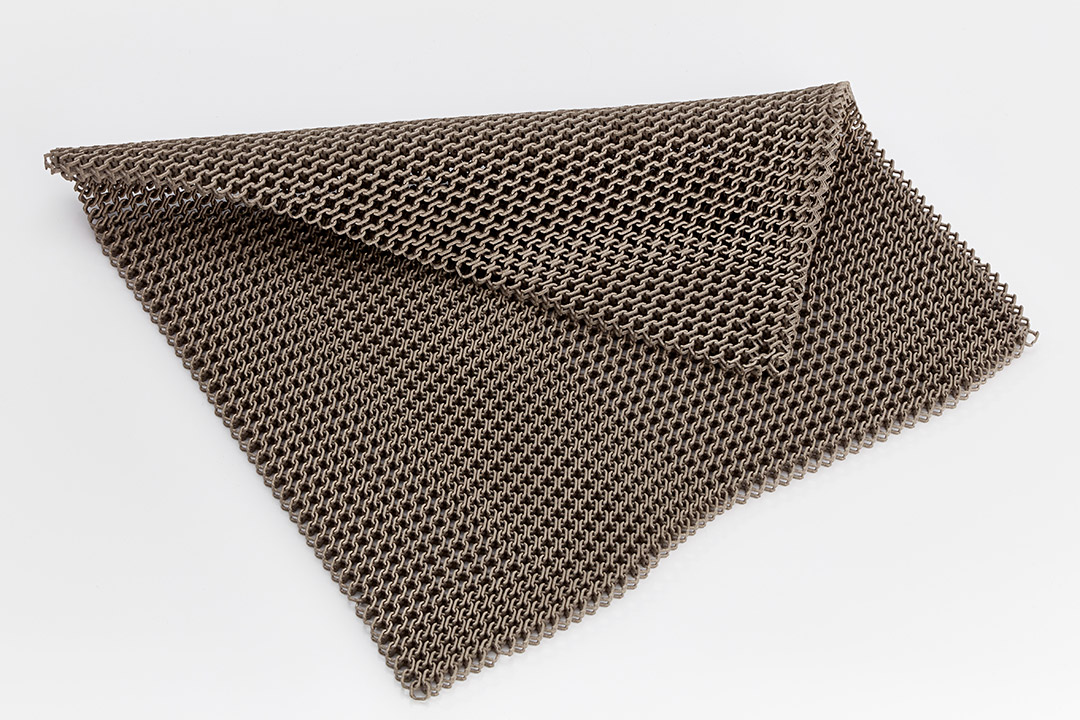

FDM—also known as Fuel deposition modeling—is a type of 3D printing that is commonly used for production, modeling, and prototyping. It is a useful type of 3D printing because it allows the use of multiple materials when printing, which creates products with multiple properties. FDM is also known as solid based additive manufacturing technology because, while layering the model, a metal wire or a plastic filament is unwound from a wire and set on the model. This is generally done to support an already built model, increasing the strength of the model.

The common process is that the initial material is used to create the model, which is then reinforced by a soluble support structure. Finally, another layer can be used to color the model, offering it more aesthetic options than other forms of 3D printing.

Due to its ability to utilize multiple layers, FDM isn’t as dynamic as other forms of 3D printing in regard to its ability to create more complex or flexible products. That is not to say that FDM is creates rigid and cumbersome products—it should be noted that it is still afforded the ability to create flexible products—but FDM is less flexible when compared to its competition.

SLS 3D Printing

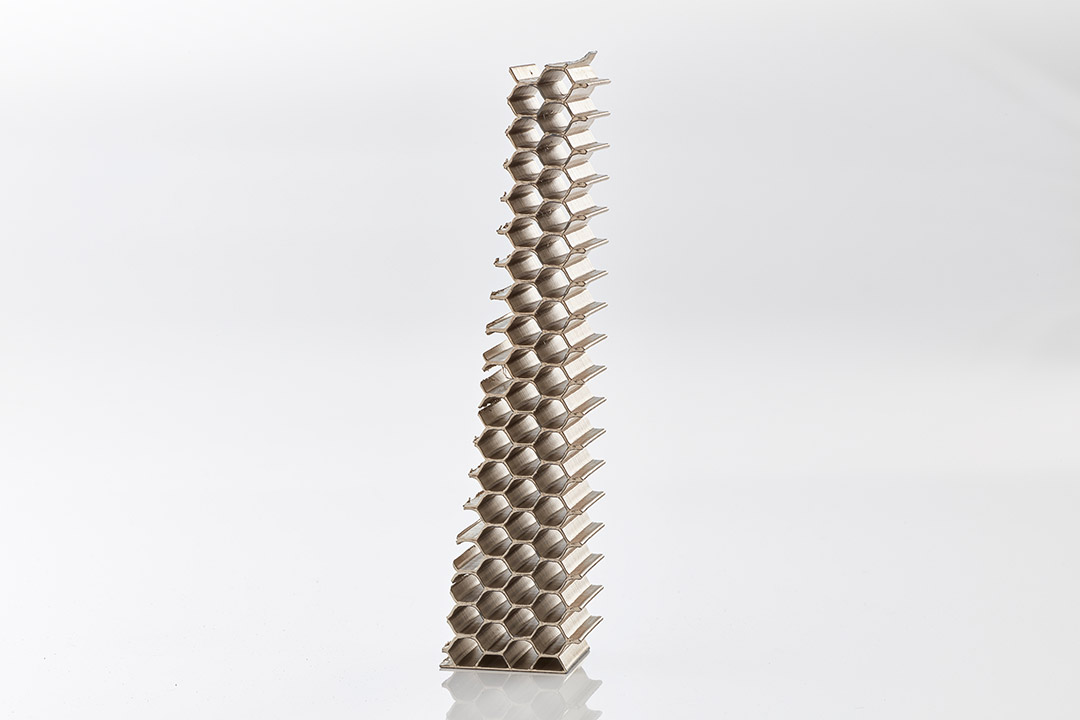

SLS—also known as selective laser sintering—is a type of 3D printing in which a laser is used to adhere different types of thermoplastic powders together to create a three dimensional model. Through the aid of CAD, a 3D design model is loaded onto a computer, which then fabricates a physical model of the design.

Since SLS doesn’t need a support feeder when creating its models, it is afforded the ability to create incredibly complex designs that were previously too difficult to produce under different means. This gives SLS an incredibly range of design options that is unrivaled by most types of 3D printing.

Since most space is utilized during the actual printing process, the cost of printing is significantly cheaper due to the fact that multiple, separate pieces can be printed simultaneously.

One drawback of SLS is the fact that it is unable to print a product that is both hollow and enclosed. This is due to the fact that powder is fused together rather than printed layer by layer. This inhibits some printing capabilities for SLS.