An Introduction to Electroplating in Engineering and Manufacturing

What Is Electroplating?

A popular metal finishing process, electroplating is used in a variety of industries for a wide range of applications. The electroplating process uses an electric current to deposit a thin layer of material on top of an object. It’s primarily used to increase wear resistance, protect against corrosion, provide conductivity , or change the aesthetic appeal of an object. In aerospace, automotive, computer, military, space exploration, medical device, healthcare, telecom, and other industries, it’s also used to add conductivity, heat resistance, help prevent oxidation, and to meet the demands of engineering teams for unique material combinations.

Common Electroplated Finishes

Electroplating can be done using several metals, including gold, rhodium, nickel, copper, tin, and, along with alloys made with a combination of these metals with others.

Nickel and Zinc-Nickel Electroplating:

Nickel is the most common electroplated material. It’s typically used in a multi-layered process, to increase wear and corrosion resistance. With heat treatment, this wear resistance can be improved even more. Nickel is also used in alloys, to increase elemental resistance, electrical conductivity, and strength/hardness. Recent developments include aesthetic coatings in satin, pearl, and black for use in automotive, motorcycle, and other vehicles, along with consumer goods like bathroom faucets, cupboard fixtures, furniture, and consumer electronics.

Aircraft Parts and components are highly susceptible to atmospheric corrosion. Corrosion can negatively impact titanium, aluminum, steel, and magnesium components, weakening their structural integrity. Plating with a nickel-zinc alloy can help address this common concern among aircraft and aerospace manufacturers.

Copper Electroplating:

Copper is second in electroplating popularity only to nickel. An exceptional electrical conductor, it is often used as an undercoat for other metals that are more durable. Copper is sometimes used to smooth out imperfections when the base piece has pitting or other surface imperfections. It can also be used for its antibacterial properties or when it’s desirable for the object to have a bright, shiny finish.

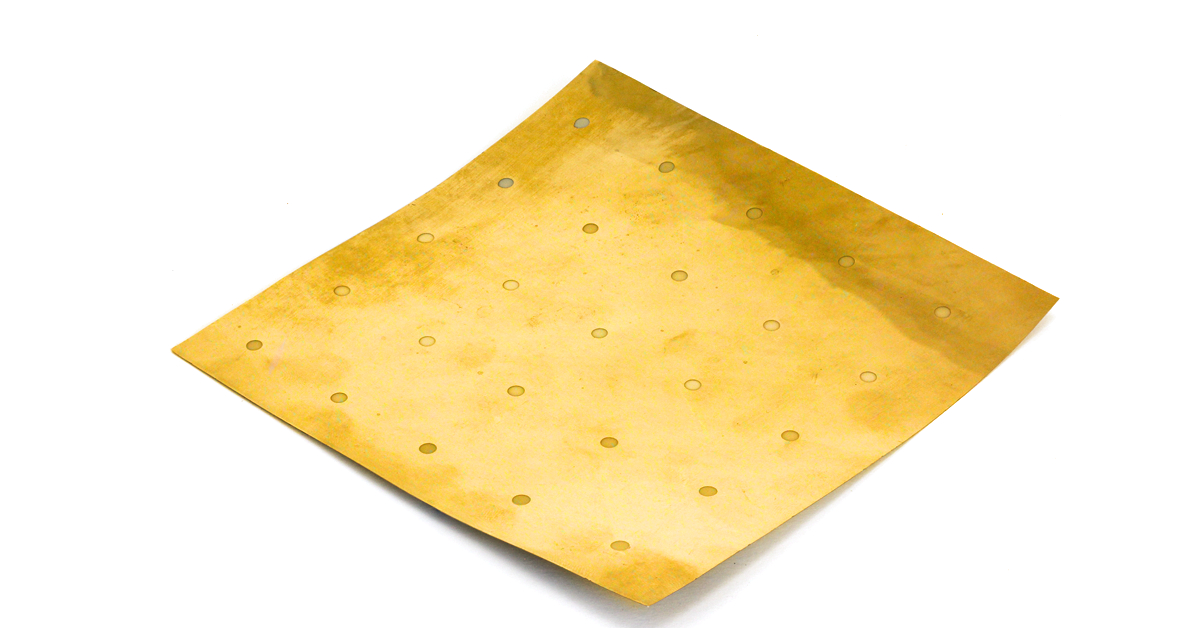

Gold Electroplating

Electroplating using gold adds high corrosion, tarnish and wear resistance, conductivity, and aesthetic appeal. It also offers these additional functional benefits in industrial use:

- Electrical conductivity: Gold naturally conducts electricity, so it’s a good choice for parts in electronics manufacturing.

- Wear resistance: Gold increases resistance to normal wear and tear, which can be critical in electronic or heavy industry use.

- Corrosion prevention: Adding a gold coating to an industrial piece helps reduce corrosion and lengthens the time an object is useful.

- Heat resistance: Electroplating using gold creates a heat shield effect, protecting the substrate in high-temperature environments.

Gold can be electroplated to several other metals, as well as polymers. In many cases, pieces may be plated with copper, silver, or nickel, adding a final gold layer for aesthetics. Compared to other electroplating metals, gold has a higher cost, which changes with the prices on the fluctuating gold market.

Benefits of Electroplating:

Why is electroplating used in so many industries, for both industrial and consumer applications? Because it’s incredibly versatile. Here are some of the benefits of manufacturing and product applications:

- Protective barrier: Electroplated parts can last longer with the protective barrier that’s applied during electroplating. They can hold up better under extreme heat and cold conditions, and more readily resist corrosion.

- Improve aesthetics: Electroplating is commonly used to enhance the appearance of products, from jewelry to automotive interiors. It’s cost-effective and can be used to create a look of luxury.

- Reduce friction: Electroplating can improve performance, by reducing friction in products like electrical connectors. Nickel plating is frequently used for this purpose.

- Electricity conductivity: Silver plating enhances electrical conductivity, a cost-effective and efficient option for manufacturers of electrical components, and electronic products.

- Oxygen absorption: Electroplating an item with palladium absorbs excess oxygen from the manufacturing of automotive catalytic converters, improving their performance.

- Whisker prevention: An alloy of zinc and nickel can help prevent the formation of whiskers, which are sharp protrusions that can occur during manufacturing operations. These whiskers can cause damage from arcing and shorts in electrical parts and components. Electroplating with this zinc-nickel alloy can significantly reduce this type of damage.

- Heat resistance: Gold and zinc-nickel alloys can be electroplated onto engine parts and components to reduce damage from extreme temperatures. This increases the parts/components lifespan and means they can better withstand extremely high temperatures.

- Hardness: Electroplating can be used to make surfaces harder, making brittle materials much stronger and extending the lifespan of the plated object. Plated surfaces are also less susceptible to damage from being dropped or struck.

- Added adhesion: Copper is often electroplated onto a piece when it needs to have a more smooth and uniform finish. It’s an ideal way to provide an undercoating for adhesion or for additional plating with other materials.

- Added thickness: There are times when a product needs to have an added thickness for the overall quality and longevity of the finish. Copper-nickel plating is a popular choice in manufacturing situations that call for higher thicknesses.

- EMI Shielding: Electromagnetism, especially in aircraft, can pose a threat when it begins interfering with the operations of other components. EMI-shielded housings can successfully isolate electromagnetic interference where it counts the most.

What are the Shortcomings of Electroplating?

Electroplating has an incredible number of benefits to many industries, including aerospace, defense, and automotive corporations. However, the electroplating process is one of precision, and not every company has the ability to meet the levels of diligence and experience to do it correctly. Perfection is required and solid electroplating is dependent on both exacting specifications of the electrochemical process and consistent, thorough preparation. It is truly a science.

The electroplating process is rife with opportunities for errors that could prove expensive and even catastrophic if not executed correctly. The process is complex and at times, the electroplating defects come after issues that are already present on the object to be electroplated, before the electroplating process starts. Those problems can include pitting, sharp edges, cold shuts, unclean manufacturing, and cleavage points, which we will dive into further later in this article.

Electroplating involves both chemistry and metallurgy, relying very heavily on proper, impeccable execution. With plating being such a critical part of the operations and products of so many industries – like aerospace, automotive, telecommunications, and more – getting the job done by a firm with a stellar reputation and a long list of references is important.

Electroplating requires precise preparation in order to be properly executed. Many of the problems arise because of problems with pre-coating defects, while others occur after plating. To help you better understand electroplating and its challenges, here are some of the defects that can present themselves during the electroplating process:

- Cold shuts: A common defect that we find in materials that are sent to us for electroplating is cold shuts. They happen when the metal has hardened at different stages, evident in the metal as flow marks or lines on the surface. Temperature differences between molten metal and a cold die can cause rapid cooling of the molten metal, so it hardens before it completely fills in the mold.The next flow of molten metal then fills the gaps between the die and the previous molten metal flow. This causes different “chunks” of hardened metal, instead of one piece of hardened metal. The piece that’s created now has less strength and will fracture along those fault lines when strained.

- Pitting: This is evident as small holes on the surface of the object. This can be related to non-permanent chemical fume suppressants used during production, though good quality permanent fume suppressants don’t seem to cause the same pitting problem. Pitting is usually caused by preparation mistakes, like inadequate cleaning or flaws on the piece. Pre-plating polishing, blasting, and grinding can also cause an issue, leaving very small particulate debris on the object. Oxidation, microscopic holes and fissures, and small pieces of non-metallic substances can also contribute to pitting. Additionally, wire brush debris, blaster remnants, and oil can also cause pitting in electroplated materials.

- Sharp edges: Objects receive electroplating based on their geometry. The process relies on electrical current, which then creates a chemical reaction on the piece’s surface, attracting cations. Some geometric shapes will receive electroplating better, attracting more cations than others. More specifically, when the electrical current passes through a to-be-plated object that has a sharp edge, the current density increases at a sharp edge. This can result in a thicker distribution of the coating metal, giving you a brittle plating layer that is likely to crack. Most manufacturing operations will grind and deburr edges on the objects to be plated, until they aren’t as sharp, with a common rule of thumb is you should round off all edges until the radius measures 0.4 to 0.8 millimeters.

- Cleavage points: When a solid splits along a structural plane, it’s called cleavage. When electroplating an object with cleavage points, these areas can cause issues with structural integrity.

- Unclean manufacturing: The cleanliness of the object to be plated is critical to successful electroplating. Unclean surfaces can result from manufacturing problems, handling, contamination of the object, or contamination of the equipment. An experienced and well-qualified electroplating tech should always examine objects closely for cleanliness before plating. An improperly prepared surface will not allow the right final adhesion to happen between the object and the coating, which can result in bubbling and blistering.

- Loss of adhesion: Loss of adhesion between the object and the electroplated coating is one of the most common types of electroplating failure. In most cases, it is a result of the surface of the object to be coated not being properly prepared. The surface must be “active,” aka ready to receive the plating. Oils, die-release agents, oxides, alloying substances, and oils can compromise this adhesion.

To help avoid this issue, most credible electroplating operations have a pretreatment system built into their plating process. This pretreatment generally involves presoaking the object in alkaline liquid, electro-cleaning the object, pickling it in acid, deoxidizing it, descaling it with chemicals, cleaning it ultrasonically, and activating strikes. The process varies depending on the materials and the object being plated, as well as between electroplating facilities.

Manufacturers can help electroplating companies avoid these and other issues by doing the following:

- Inform the plater exactly what alloy is being used. Even a variance of 5% in the alloys make-up can require a different pretreatment and plating technique.

- Use oils that are less difficult to remove. Organic oils like vegetable and animal oils are more easily removed than silicon wax and lubricants.

- Heat-treat in an inert environment. While it’s more expensive, it requires significantly less pretreatment so it can save money.

- Use plating-grade materials. A finished plating job cannot turn out defect-free if the materials used aren’t of high quality. Materials that don’t meet plating standards often include metallic inclusions and residues on their surfaces.

Hydrogen Cracking

When working with finishing metals, hydrogen can cause them to become brittle, break, and fracture. Unfortunately, hydrogen can work its way into parts without the manufacturer’s knowledge. This type of embrittlement typically shows up after the plating process has been completed and when the part/object is put under stress. To help minimize hydrogen cracking, engineers may try several measures, including stress relief baking and peening the object with a shot. Both of these processes help promote strength.

Hazy or Dull Deposits

Hazy or dull spots on a plating surface may have several potential causes, including:

Chemical Imbalance

Insufficient levels of Dura Additive or an excessive level of sulfate, chromic acid, or contaminants in the object bath can result in dull or hazy deposits in the product plating. It can be caused by any of the following factors.

- Improper rectifier functioning: The rectifier you’re using in the electroplating process must be in proper working order, or you risk dull deposits. A credible electroplating company will perform tests regularly to look for and perform, any necessary repairs.

- Inadequate preheating: If the parts being electroplated aren’t hot enough, it can lead to defects. The objects need to be warmed to the bath temperature consistently, all through their mass.

- Interrupted current: When the electroplating current isn’t consistent or gets interrupted, the results will be adversely affected.

- Incorrect bath temperature: While plating bath parameters can differ, the bath temperature should typically be between 130 and 140 degrees Fahrenheit. It’s critical to keep the temperature consistent and stay within two degrees Fahrenheit.

- Incorrect current density: The correct current density is two ASI. Any deviation from this level can lead to haziness and dullness in the finish.

- Incorrect current distribution: The anodes must be the correct distance from the object or the current won’t flow correctly. The use of conforming anodes helps to solve this issue.

- Inadequate rinse: Objects must be rinsed thoroughly, ensuring the removal of all cleansers, chemicals, solvents, or oils. Any residue left on a part can cause adhesion problems.

- Part sitting too high in the solution: The object to be plated must be submerged at least 4 inches below the surface of the solution, in order to receive the proper amount of current.

- Organic compound contamination: Over time, organic substances can form a scum on the surface of the bath. That scum can then end up coating the object being plated.

Blistering in Electroplating

When gas expands in the pores of the object being plated, typically hydrogen or nitrogen, blisters can erupt on the surface of the plating. This typically happens when an object is heated, the gases expand and cause the plating to blister off of the surface.

Oxidation in Electroplating

Objects are often electroplated to prevent oxidation, though manufacturers must be mindful of making sure the object hasn’t already oxidized before it is plated. Oxidation results in poor adhesion of the plating to the object, contributing to lift.

Electroplating Common and Best Practices

Check out these common and best practices for electroplating.

- Prepare the object surface. Solid electroplating requires prepping to ensure the piece you’re plating is “active” and ready for the coating. Manufacturers use techniques like blasting, washing, rinsing, and acid baths to eliminate all surface imperfections.

- Pay close attention to chemistry. Different solutions can affect alloys in different ways. Paying close attention to the solution that’s recommended for the specific object material will result in the best appearance and functionality of the plating.

- Monitor the age and quality of the bath. Over time, byproducts of chemical reactions can degrade the chemical baths being used in electroplating. Don’t allow the bath to degrade below the desired level, or the quality of the coating will be impacted.

- Keep the bath depth consistent. Every time an item is coated in a bath, some of the solutions is used and the volume of the bath is reduced. It’s critical to keep measuring the volume and chemistry of the solution before every plating.

- Keep consistent temperatures. Electroplating with metal can be drastically impacted by temperature. Lower temps make the process take longer, though if the temperature is too high, the process happens too quickly. Both of these effects cause problems in the plating. Temperatures must be monitored consistently during the plating process, preferably via an automated process, to help avoid these problems.

- Use heat treatment after coating. Post-treatment, heat can be used to improve the hardness of a nickel or alloy coating.

Electroplating Plastics

Plastics have been engineered for use in innumerable industries and products around the globe. Plastics made of modern polymers are popular in aerospace, automotive, aeronautics, health care equipment, and other high tech industries for their easy machinability, excellent surface finishes, lightweight, and overall versatility. Electroplating plastics also allows engineering teams to take advantage of the economies of scale that have made injection molding immensely popular for large-scale production.

While the majority of electroplating is done on metal, plating metal onto plastics and polymers allows engineers to use polymer/metal combinations to create unique physical characteristics. Electroplating plastics adds additional properties that make it even more valuable for use in industry, like:

- Electromagnetic Interference shielding (EMI)

- Wear protection

- Corrosion resistance

- Increased surface hardness

- Electrical conductivity

- Improved appearance

- Add solderability

- Chemical resistivity

- Increased thermal range

Electroplating transforms a non-conductive plastic surface to one that conducts electricity. This means that manufacturers of electronic components used in automobiles, planes, spacecraft, and a myriad of other products can build lighter products that conduct electricity. The metal coating can also be used to reflect damaging light away from the surface of a plastic object, and serve as a barrier against detrimental substances, wear, corrosion, and EMI. A metal coating can also help reduce energy dissipation.

Manufacturers get plastic parts electroplated in order to protect the parts from chemicals that could damage them, slow down corrosion, and increase wear and strength. The process can also be used to create an impression of increased quality and luxury.

Plating 3D Printed Parts

Thermoplastics are commonly used in 3D printing components and parts, specifically polycarbonate, polystyrene, polyacetal, polypropylene, and blended nylons. However, some 3D printing methods are also able to extrude parts using titanium, steel, and wax, materials that are very rarely plated.

The use of 3D printed parts has become critical to the medical, engineering design, and automotive industries. The ability to extrude complete prototypes and early models of equipment and vehicles from scratch has quickly made this process invaluable to engineering teams around the globe.

When plating 3D printed parts, the type of material to be used for the plating is an important decision. If the material being used for the component is a chemically-resistant plastic, it will be more difficult to plate. Plating plastics requires a chemical surface treatment as a pretreatment to improve adhesion.

Plating for 3D printed parts is done for both aesthetic and functional reasons. Silver, for example, can enhance a product’s aesthetic while making it more resistant to corrosion. Metal plating for 3D printed parts provides functional benefits, too, improving resistance to heat, corrosion, and chemicals, shielding from EMI and RFI, and increasing strength.

Electroplating Injection Molded Plastic Components

When manufacturing injected molded plastic parts for electroplating, there are several processes that need to be carefully followed, including:

- The use of palatable resin compounds can minimize the difficulties in surface adhesion that comes with high molded-in stresses

- Minimizing the residence time of the resin in the injection barrel can help avoid the potential degradation that can negatively affect the ability to plate the plastic.

- The resin must be properly dried to avoid blistering and moisture-related surface issues after plating.

- Pristine injection molding processes are essential. All pieces and areas around the molding machine must be free of contaminants like cleaning chemicals, oil, and grease.

- When handling injection molded parts, wear the proper gloves to reduce the oils that can come with fingerprints.

- All molded parts must be put into protective packaging immediately, to avoid dust and protect it until it is plated.

Challenges in Electroplating Plastic

Unfortunately, plastics aren’t electrically conductive, so they can be challenging to plate and proper adhesion can be difficult to achieve. Achieving excellent adhesion and RF performance is critical, as many of these plated plastics will be utilized in extreme temperature conditions.

Plastic objects must be properly prepared before being coated. Often, this involves being chemically cleaned and stripped of contaminants, then layered with electroless copper, which doesn’t require electrical conductivity for adhesion. Additional metals or alloys, like nickel or silver, can then be adhered to the copper plating to create the desired properties in the final plated object.

Electroplating Metals

There are several appealing reasons for electroplating metals. Some are more expensive than others or have different desirable qualities. The process has been in use since the early 19th century.

For example, gold and silver are considered top metals, both rare and expensive. Jewelers create less expensive pieces by electroplating a thin layer of gold or silver over a less valuable metal. Thin layers of chromium, another shiny metal, have been used for decades to add shine and appeal to consumer products like cars and home decor.

Metal is often electroplated onto another metal to protect the surface. For example, copper, nickel, and chromium are often used to provide a protective coating (that is less reactive) for items made of the more reactive substances zinc and cadmium.

In the electronics industry, electroplating is used to add conductivity to electronic components and circuits made of less expensive metals. Gold and silver, which are excellent (but expensive) conductors of electricity, can be electroplated onto those components, saving money for the manufacturers of cell phones, computers, and other electronic consumer products.

Composite Material and Electroplating

A composite material is made of two or more distinct constituent materials. Though the constituent ingredients remain distinct within the composite, the final product material has new properties — such as greater strength or heat resistance — as a result of the combination.

Generally, composite materials are formed by adding a reinforcement component to a matrix material, like mixing gravel with cement to create stronger material concrete. Indeed, building materials such as concrete and plywood are familiar examples of composites.

Some composites are more carefully structured than concrete, however. Engineers often weave small reinforcement fibers into a matrix, using intentional patterns to increase the material’s performance in various capacities. The matrix holds the reinforcement fibers in place, and the reinforcement provides improved properties to the matrix, preventing breaking or bending, for example.

Composites are popular for industrial applications because the wide variety of available components make composites easily customized to fit any industry or product’s unique physical requirements. A composite material can be lighter, stronger, more durable, or even less expensive than a single homogeneous material.

Electroplating on Composite Material

Composite materials are becoming increasingly popular in manufacturing and that trend is sure to continue for some time into the future. Let’s review three of the composite materials that manufacturers frequently electroplate with metal.

Glass-reinforced plastics (GRP): Glass-reinforced plastics are overall more economical than carbon alloy steels, stainless steels, high nickel alloys, or titanium materials, with a density of about one-quarter of the steel material. GRP is also light in weight, easy to repair, and allows electrical conductivity to be safely used, where it would typically not be tolerated.

Fiber-reinforced plastics (FRP): FRP is created by using fibers as reinforcement for a plastic matrix. These fibers can be carbon or glass. Electroplating FRP typically involves a layer of electroless nickel, to provide a base for electroplating.

Metal matrix composites (MMCs): Metal matrix composites are made up of a metal reinforcement material embedded into a metal matrix. These materials get plated using a similar process to other electroplating projects.

Ceramic matrix composites (CMCs): CMCs are a combination of ceramix matrix and ceramic fibers. These can include carbon and carbon fibers. To electroplate CMCs, the base will go through electroless plating so that it will conduct electricity. Typically, electroless nickel is used in preparation for traditional electroplating.

The Benefits of Plating Onto Composite Material

Composite materials are frequently used in the creation of parts in the aerospace and military industry sectors, where advanced composites can add strength, reduce weight (and thereby become more eco friendly), minimize cost, and provide a wide range of additional benefits in both form and function, depending on the materials used in the composite.

For example, a silver door handle is significantly more expensive than a door handle made of plastic that’s plated with bright nickel and chrome. A shiny metal (electroplated) finish provides a beautiful aesthetic for less.

In another scenario, some industries use composite materials because they can be used in high-performance situations. Standard ceramics aren’t as strong as ceramic composites. Ceramic composites are heat tolerant to extreme temperatures, so they can be used as heat shields for spaceships. And when you electroplate these ceramic composites with metals, you create a very heat tolerant object with electrical conductivity.

Common Electroplating Applications and Industries

Electroplating is everywhere. From automotive trim to the parts of the last rocketship you watched get launched into space, electroplated materials are used for their versatility, their conductivity, their appearance, and more. Here are a few examples of common applications:

- EMI Shielding in Electronics: Electromagnetic interference (EMI) is a concern in any situation involving electronic systems. EMI shielding using electroplating can protect a device or cabling, so that conflicting signals and interference are blocked. EMI shielding can also be used to help prevent power degradation issues in cables.

- Chrome plating in automotive trim: Many parts on cars aren’t actually all chrome; they’re chrome-plated plastics.Your “chrome” bumper is most likely made from injection-molded ABS plastic, plated with a thin layer of copper, nickel, and chromium so that it’s super shiny, more resistant to rust, and not as easy to scratch.

- Hard chrome plating on high wear surfaces: Hard chrome plating is used to increase the hardness, durability, and corrosion resistance on high wear surfaces. Chromium metal is used to add a hard, durable surface finish with improved wear, even in extreme situations. Parts last longer and resist corrosion, and chromium is less likely to wear away in harsh environments.

Emerging Applications and Cutting Edge Usage for Electroplating

Electroplating for the Aerospace Industry

Electroplating is a critical part of aerospace and satellite metal finishing, where it is used to:

- Remove mass/weight and complexity from components

- Protect against corrosion

- Increase lifespan and wear of components

- Increase heat resistance in extreme temperatures

- Add or increase electrical conductivity

- Increase resistance to oxidation

- Add strength to metal substrates and components

- Add to the visual aesthetic

Spacecraft and satellites face numerous environmental threats, both within the atmosphere and outside of it, that can degrade and damage equipment and materials. Additional threats that can be mitigated or met by electroplating include:

- Powerful light: The light from the sun is incredibly powerful and without protection from the earth’s atmosphere, satellites and spacecraft are exposed to huge amounts of sunlight, causing heat and glare. Metal insulation plating can help reflect and absorb this damaging light.

- Heat: The sun’s heat is incredibly stronger outside of the earth’s atmosphere. Reflective coatings and metal plating are used to transfer heat to help mitigate damage to electronic equipment.

- Temperature Cycling: Satellites and spacecraft can go through many cycles of extreme heat and extreme cold in one day. Metal coatings can be used to minimize the effects of these quick thermal changes on equipment and the crafts themselves.

- Space Garbage: Satellites and spacecraft are subject to being hit by small objects in space, whether those objects are natural in the form of micrometeoroids or man-made space junk. Strong metal coatings can help protect the craft or satellite’s exterior.

Electroplating for the Defense Industry

Equipment that’s used by our nation’s military must be able to withstand extreme temperatures, high and near-constant use, high levels of friction, and other issues that will be encountered in service and combat situations. Most materials in these use situations must be coated with metal finishes to address: electrical conductivity, hardness, oxygen deprivation or saturation, chemical and caustic materials exposure, insulation, and other extremes. In defense applications, electroplating requires strict adherence to provided specifications that are provided by the Department of Defense and defense contract manufacturers.

Electroplating for Electric Vehicles and Future Mobility

The need to create lighter and more aerodynamic vehicles for all of the new forms of future mobility has created increasing and renewed interest in electroplating on plastic. Automotive manufacturers are using more electroplated injection-molded parts in electric vehicles, for internal engine components, connector and interconnect device housings, exterior trim and panels, and battery housings, among other uses.

Electroplating for the Medical Device Industry

Medical devices and implants that are placed inside the body are required to meet high standards for sanitation, reliability, durability, and safety. Many of these products rely on metal electroplating to ensure the product is of the highest quality, clean, and free of defects that could cause a problem for the patient. Here are just a few examples of electroplating in use in the medical device industry:

- Gold is often used due to its high biocompatibility, corrosion resistance, and electrical conductivity. It’s used often for arterial stents, pacemakers, and dental crowns, among other uses.

- Silver has antibacterial properties, making it a good choice for the medical plating of tools and equipment.

- Platinum is hard, corrosion-resistant, and biocompatible, so it makes a great choice for catheters, pacemakers, and implants.

Why SAT Plating?

We are Veteran led, family-owned, and operated. We develop technical solutions for the aerospace, defense, automotive, and medical device industries, who come to us when they need to apply metal platings to high performance engineered polymers.

We take great pride in how we deliver controlled and repeatable technical solutions. Our Quality FIRST mission means that we’re focused on our managerial commitment to quality and to you, our customer. We aim to improve every day, with every product we make. We aim to reduce and identify risk, surpass the requirements for any and all requested products, meet or exceed your expectations; and work together as a happy and efficient team.

Learn more about us here: https://www.satplating.com/about-us/