Plating Composite Polymers, Hybrid & Exotic Materials

Plating composite polymers and hybrid materials provide a range of applications since it combines the strongest traits from various materials, whether a combination of plastics, glass, carbon fiber, metals or others.

Each year, new composites or hybrid materials are created in our industry. These are usually combinations of elements such as metal and/or polymeric fillers, non-woven fibers, woven fibers, epoxies, urethanes, acrylics, nano-particles, and so on, developed to solve specific performance requirements for a customer. SAT works with the customer to identify processing chemicals and plating techniques to metalize these unique and challenging substrates.

As examples, SAT successfully plates:

- Glass filled PEEK, Ultem, Nylon, and many others

- Carbon Fiber filled PEEK, Ultem, Nylon, etc

- Metallic powers materials mixed with polymers and injection molded

Composite Polymers & Hybrid Materials can be created to specially cater to differing situations in which a single polymer couldn’t fully handle alone. Along with their flexible capabilities, Composite & Hybrid Materials are also incredibly dynamic.

Along with their dynamic potential for the properties of the material, Composite & Hybrid Materials also boast a wide array of usages when combined with a plated metal surface. With plating, a product then has aesthetic and EMI shielding properties, for example.

A Closer Look At Composite Polymers, Hybrid & Exotic Materials

Composite Polymer & Hybrid Materials are created from combining multiple components into a single substrate, allowing for the creation of materials with dynamic properties that can boast a multitude of uses depending on the application in which they would be used. Composite & Hybrid Materials are especially ideal for situations where a component will be exposed to extreme environments – either extreme cold, extreme heat, or the conditions found outside Earth’s atmosphere.

These are situations where the properties of a single polymer simply wouldn’t suffice. This dynamicity makes Composite & Hybrid Materials some of the most useful and resilient forms of polymers.

An important factor to note when specifically discussing a Hybrid Material is the fact that it doesn’t have one single, consistent form. Since they are a combination of multiple types of materials, Hybrid Materials differ from application to application. Because of this, they are typically specialized and created for a specific use rather than having a multitude of differing applications.

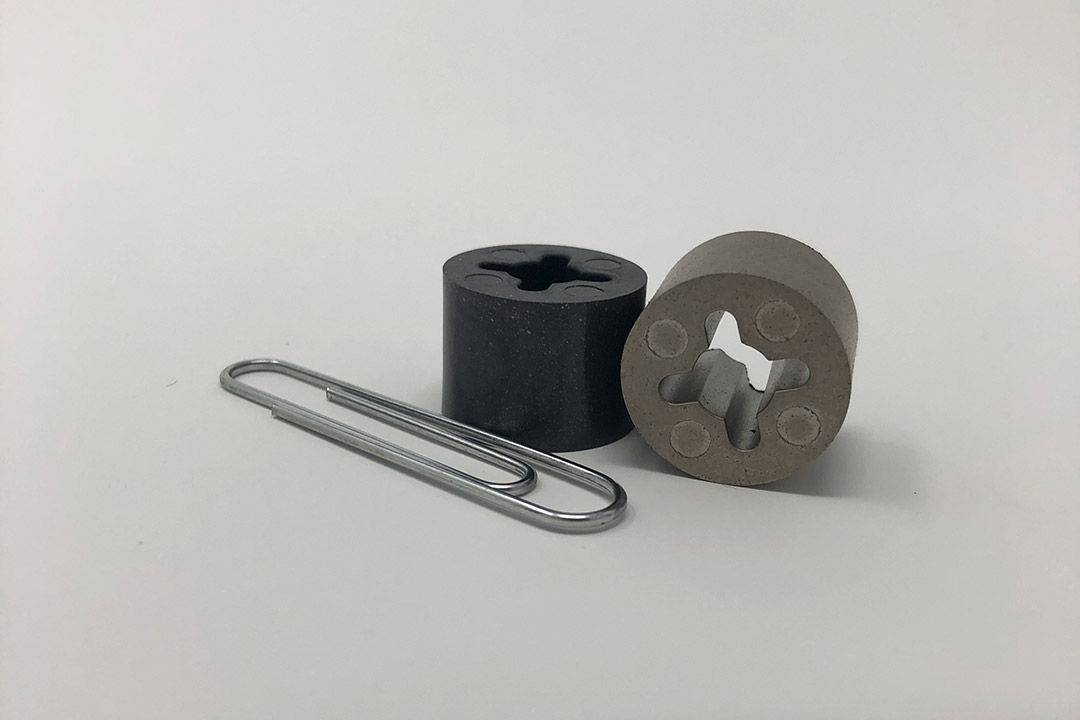

Since Composite & Hybrid Materials are highly specialized, they’re also able to take on a multitude of properties from their base polymers. For example, when PEEK is combined with Carbon Fiber, it combines the strength and the heat resistance of Carbon Fiber with the inherent stability PEEK naturally has. This creates a superior substrate that combines the strengths of both materials, creating a product that can meet extreme requirements.

Composite Polymers & Hybrid Materials can also deliver cost savings when a less expensive material is mixed into a pure resin. An example of this is seen when glass is added to Ultem®.