We Plate High-Performance Plastics.

Our proprietary capabilities allow us to plate the most advanced composite and high performance materials in the world.Plating Injection Molded Composite Connectors

There are thousands of connectors on airplanes, defense systems, and vehicles. The high performance and highly technical interfaces utilized in these electronic systems require durability, corrosion resistance, and production consistency. These specifications make the concept of using injection molded and plated connectors a smart choice for any advanced wiring system.

More specifically, injection molding with innovative polymers like PEEK and Ultem (PEI) offers enhanced functionality and performance while accommodating the market’s demand for the cost savings that light-weighting products can provide. Plating these parts with metals adds desirable qualities such as EMI shielding and corrosion protection. Learn more about the advantages of innovative injection molded and plated connectors..

Electroplating and EMI Shielding

The need for EMI shielding continues to grow in many industries as technological advancements increase the use of sensitive electronics, mobile communication devices, and GPS tracking, among other exciting technologies.

EMI shielding helps protect against signal disruption by preventing external signals from disrupting any given component, through an enclosure around the sensitive part. Alternatively, shielding can be used to prevent devices that generate disruptive waves from impacting nearby components by enclosing the disruptive equipment. Learn more about the myriad applications of electroplating and EMI Shielding across industries…

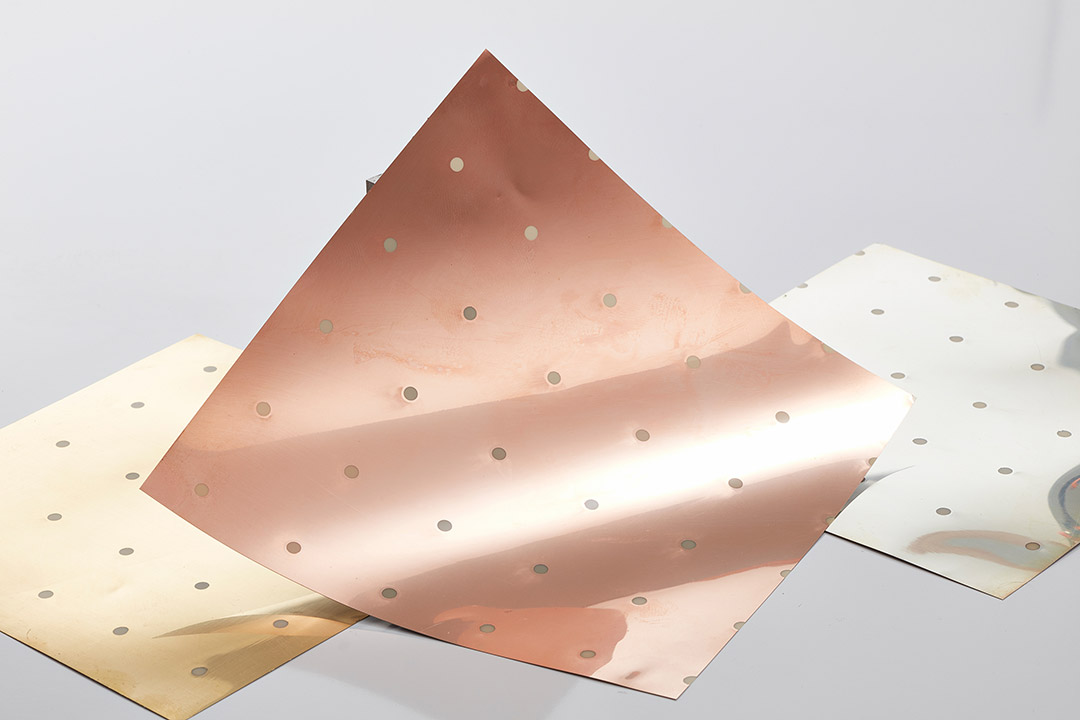

Plating Hybrid & Exotic Materials

Are you developing a new material that needs to be plated? We work with all types of advanced technology companies to develop new products utilizing the most advanced and compound hybrid materials on earth. We plate composites made with metal and plastic that include mixtures of all different components such as injection molded magnets and plated carbon fiber.