Plating PEEK

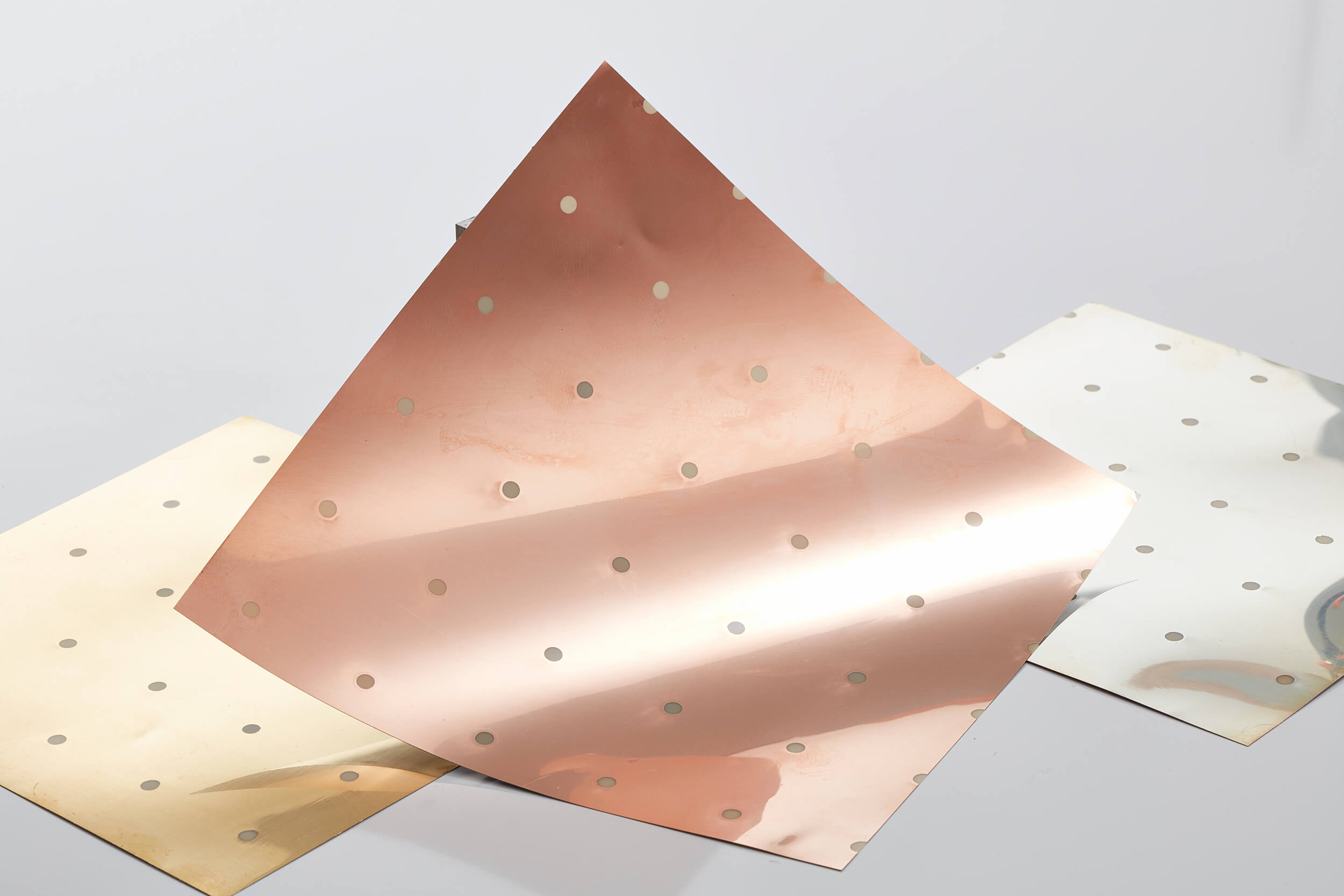

We’ve developed advanced technologies for plating numerous grades of PEEK with high adhesion.

Our proprietary Surface Activation® technology allows us to plate films, fibers, fabrics, powders, molded and additive manufactured materials of PEEK. No abrasive blasting or chemical erosion is needed, so the dimensions and finishes of your material remain “as-molded”.

Our process is highly repeatable and scalable, with plating yields far above competing processes.

PEEK is also commonly combined with carbon fiber, glass, and other materials in order to meet specific performance characteristics.

Why Use PEEK?

Surviving in outer space and inside the human body, plated PEEK can be subjected to extreme conditions, and yet still meet performance specifications. PEEK’s usefulness is strengthened by the fact that it meets many material requirements for aerospace, medical, and industrial applications.

PEEK can be combined with carbon fiber, glass and other materials to meet different performance characteristics.

Our plating capabilities can meet the performance requirements of your PEEK component.

PEEK resins can be injection molded, machined, and even used with rapid 3D printers. This flexibility, plus its extreme chemical resistance and lightness, make it a logical alternative to metal components. In medical applications, PEEK is also widely accepted as the “go-to” material for bio-compatibility.

A Closer look at PEEK

PEEK—also known as Polyether Ether Ketone (PEEK)—is an organic thermoplastic polymer found within the PAEK—Polyaryletherketone—family. PEEK offers high mechanical and chemical resistance that can be sustained over high temperatures. With a melting point of 662 °F (343 °C), PEEK offers a dynamic application ranging from aerospace technology to exposure to steam or even high water pressure. The flexibility of PEEK’s use affords it a wide array of uses within the medical field, ranging from dental implants, to surgical implants, to dialysis pump filters. All of these applications are possible due to PEEK’s high stress tolerance, giving it a great degree of longevity.

PEEK’s high strength comes from its resilient resistance to several factors. One of the major factors is its chemical resistance. PEEK offers a high resistance to post irradiation radiation, which allows the material to be sterilized by both gamma and electron beam radiation. PEEK’s high melting point also makes it ideal for medical application since it will rarely (if ever) be exposed to materials above 662 °F. The material’s strength and resilience allows it to avoid degradation due to stress, making it ideal for long term solutions.

Our typical customers include purchasing decision makers on behalf of medical, industrial, automotive, and aerospace industries.

Beyond PEEK’s longevity, it also offers an enhanced overall performance. PEEK can withstand and eliminate corrosion, it offers lower friction when used, and can operate in some of the most extreme environments. PEEK is also very light, offering half the low specific gravity of aluminum and a sixth of the low specific gravity of steel. This weight differential increases PEEK’s lifespan since its lower weight subjects it to less overall stress. The increased efficiency also affords less overall waste since less material is used. It also carries the potential to be reused and recycled due to its thermoplastic nature.

Since PEEK is a thermoplastic, it also allows the material malleability, thus creating the potential for dynamic design. PEEK can be molded into various shapes, which allows it to increase the practicality of its application. This is one of the reasons why PEEK is a popular 3-D printing material.

PEEK provides significant advantages over metal parts and is the choice material aerospace, automotive, industrial, and medical industries continue to use for demanding applications.